share to

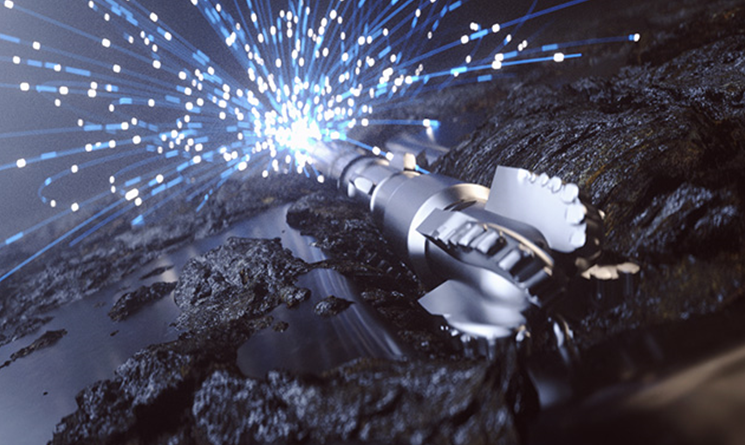

looking back to 2023, in the while drilling engineering service projects located in changhe block, yan’an, shaanxi, shenkai’s mwd instruments and lwd logging instruments have won the trust of customers from internationally renowned logging and oil service technology companies for their reliability and well inclination azimuth measurement values, high precision in measuring absolute values (including ordinary gamma gr, azimuth gamma agr, compensation resistivity ctf-6.75 and 4.75), significant geological guidance effect and the adaptability and reliability of all while drilling instruments to harsh drilling conditions (high vibration, well leakage, plugging agents, high torque, high erosion, etc.).

(hilly region of the loess plateau)

the block where shenkai provides while drilling services is a typical hilly region on the loess plateau with crisscrossing terrain and gullies, which has a ground elevation from 930 to 1562 meters, and the construction conditions are harsh. the target layer is dense sandstone with high quartz content, strong abrasiveness, and poor drillability. it requires high precision in trajectory control for construction in the horizontal section. the formation is mostly characterized by natural fractures, with a high degree of natural rupture, severe leakage occurs especially during drilling into the liujiagou, shiqianfeng, and shihezi formations, with a maximum leakage rate of 20m3 per hour. comprehensive plugging agents such as walnut shells and cottonseed wool are extensively used, which seriously affects the signal transmission of downhole while drilling tools.

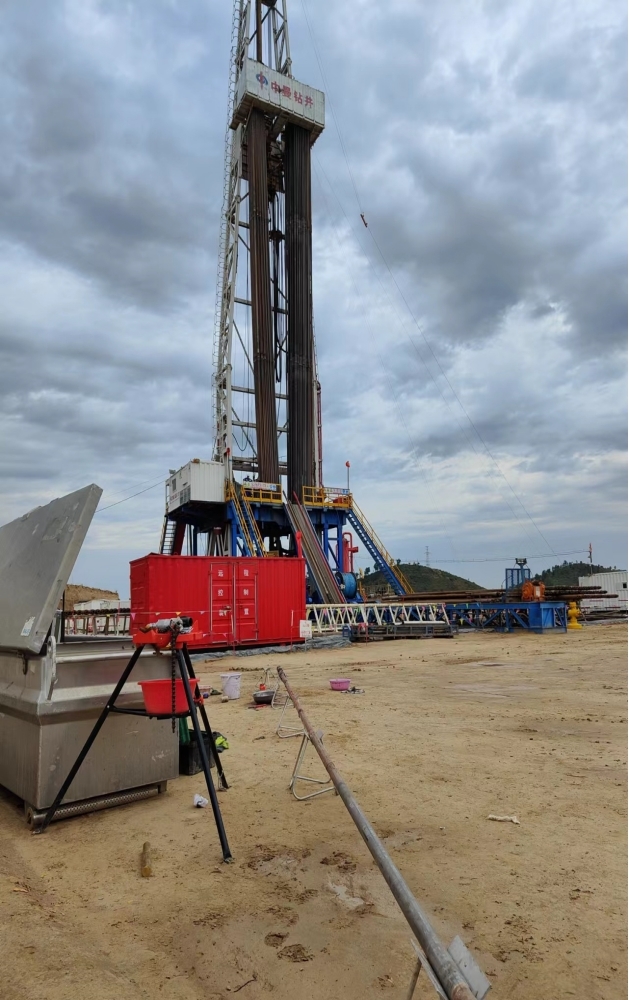

(construction site in northern shaanxi)

party a is a globally renowned logging and oil service technology company, which has high requirements for the accuracy of directional measurement values including well inclination, azimuth, tool surface, etc. of mwd, as well as the accuracy of lwd (gamma, azimuth gamma, compensation resistivity). it is required that the absolute value match the logging values. it is a necessary condition for party a to achieve high-level and precise geosteering by obtaining directional and logging parameters through precise mwd. it is also one of the core reasons for party a to achieve high single well production (with a significant increase compared to comparable well locations) by adopting precise geosteering to achieve the maximum drilling rate of the sweet spot layer.

the high precision and high-temperature stability of shenkai sk-om directional sensor are the basis for precise trajectory measurement. shenkai directional sensor testing laboratory is equipped with advanced three-coordinate measuring instruments, online temperature rise non-magnetic helmholtz calibrators, and optical three-axis non-magnetic detectors. through strict control of component accuracy, assembly accuracy, accuracy calibration, and accuracy testing, they can be used to achieve accurate temperature range of directional probe based on scientific orthogonal and linear calibration, temperature compensation algorithms, and temperature compensation algorithms.

(assembly and commissioning before going down the well)

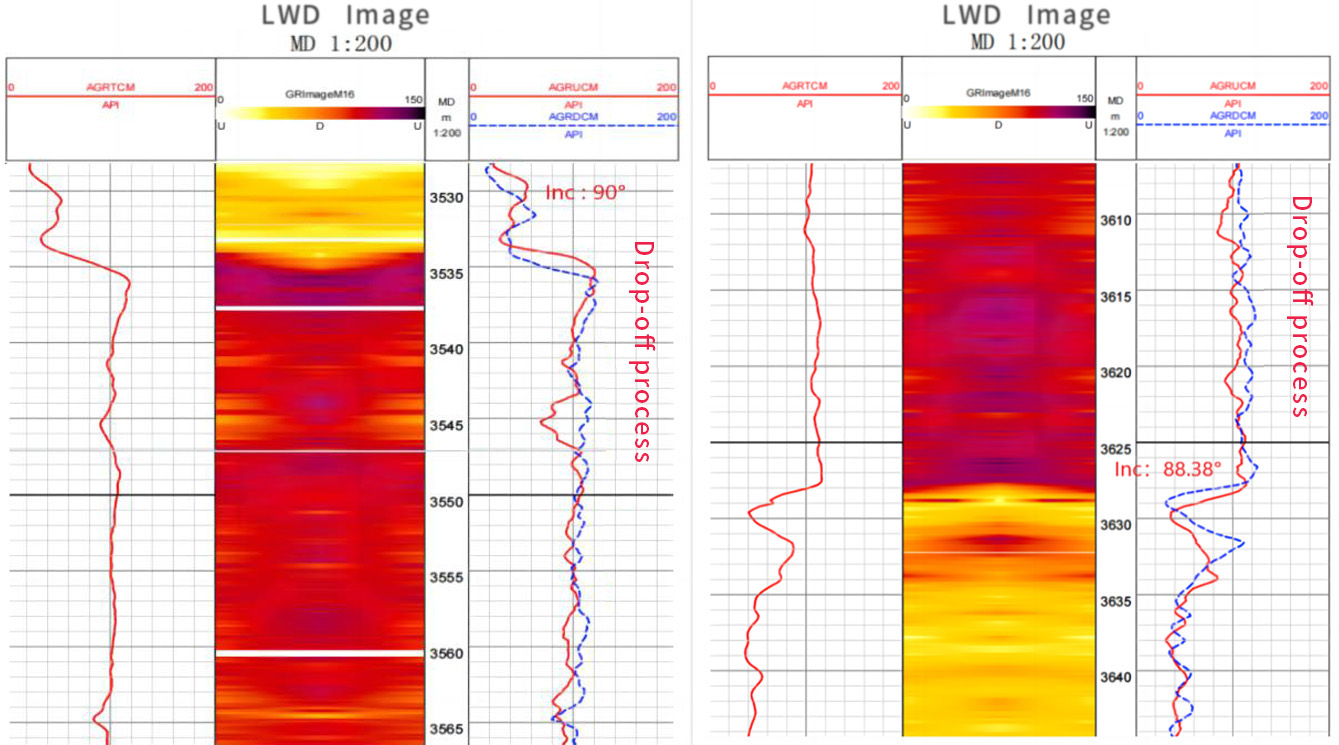

the accuracy of lwd is the basis for accurate geosteering and formation evaluation. with industry-leading crystals and photomultiplier tubes, mechanical triple vibration reduction technology, and signal circuit anti-interference technology, shenkai grs gamma sensor and agrs azimuth gamma sensor can be used to achieve precise gamma measurement and azimuth gamma sector division under high temperature, high vibration and impact conditions. shenkai high-temperature compensation resistivity ctf originates from ge and adopts international standard resistivity measurement instrument design and process standards. it adopts high-performance hardware to ensure temperature stability and also passed 42-point accuracy testing to achieve high accuracy and consistency. the calculation of instrument measurement values to the true resistivity of the formation can be guaranteed through a comprehensive and accurate resistivity correction template. shenkai farsee lwd software platform (including a complete set of gamma and resistivity wellbore correction and mud correction algorithms) can ultimately provide real formation logging data.

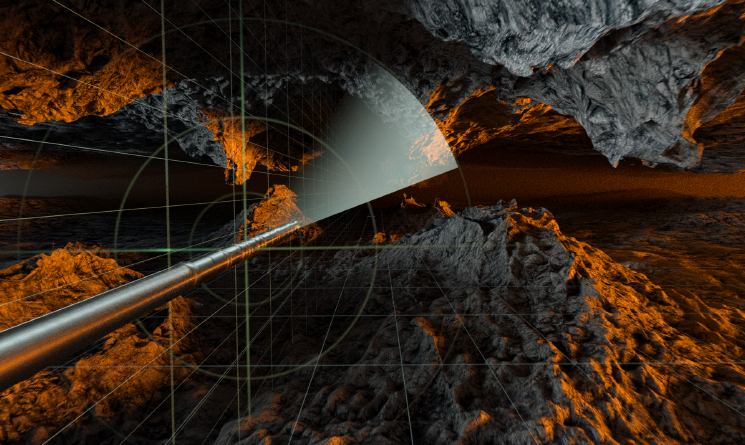

(lwd image)

after years of testing and comparison, party a finally chose shenkai as the while drilling technology service provider after comparing almost all while drilling instrument services in china, which fully demonstrates that shenkai’s mwd and lwd instruments have gained party a’s trust with their high adaptability and precise reliability in complex and harsh well conditions.

during operation, in the face of complex working conditions, shenkai has cooperated sincerely with the engineering, geological department, drilling crew, and other third parties of party a to respond and solve construction technical problems in a timely manner, break the historical records of the highest daily footage and longest horizontal footage in the horizontal section of block 113-133, and saving drilling cycles of 5-8 days for multiple wells. after nearly two years of comprehensive evaluation, the reliability, performance indicators, measurement accuracy, logging response, personnel professional ability, on-site service guarantee, etc. of shenkai while drilling instruments have been unanimously recognized by party a:

· sk-h6 upper suspension pulse generator/sk-ep lower key motor piston pulse sk-tmwd skgr/agr system have stable performance, strong resistance to erosion and plugging;

· sk-ctf-6.75/4.75 compensation resistivity measurement has high accuracy and is sensitive to geological reflection;

· sk-agr azimuth gamma accurately measures the up and down cutting relationship between reservoirs and trajectories in sand and mudstone interbeds, resulting in significant geosteering effect.

looking ahead to the future, shenkai will focus on reliable and accurate instruments, strive to become the preferred supplier of while drilling instruments for customers. at the same time, it will continue to uphold the principle of service quality first, take creating value for customers as its responsibility, continuously make technological innovation, transform and improve product performance, achieve intelligent and remote product development, collaborate with multiple specialties, generate integrated solutions, transform from a core equipment provider in the domestic petroleum industry to a provider of integrated wellsite solutions in the petroleum industry, and promote the development of the petroleum industry.