share to

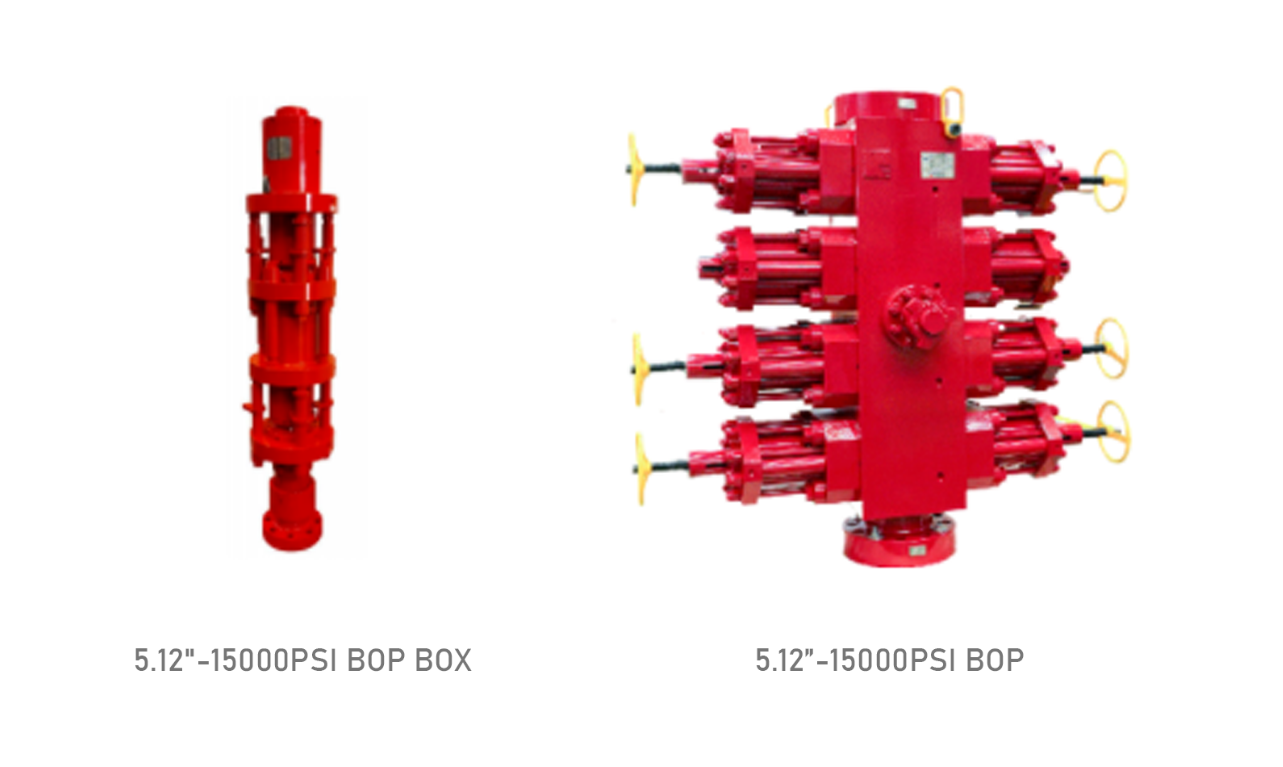

recently, it is reported from shanghai shenkai petroleum equipment co., ltd. that since being put into use, the 5.12 5.12”-15000psi four-ram bop and bop box independently developed and produced by the company have been operating normally and achieved good application results in the complex geological environment of high temperature, high pressure, and high sulfur content at the application site of an oilfield in northeast china.

to achieve localization replacement, shanghai shenkai petroleum equipment co., ltd. launched its self-developed and produced 15k continuous tubing bops in 2021 after nearly a decade of dedicated r&d and experiments since the first coiled tubing bop was launched in 2014. in just two years, the product has been successfully used in the oilfields in the northeast and east china regions, receiving high praise from customers. over the years, shenkai coiled tubing bop has been successfully applied in the major oilfields in northeast china, xinjiang, changqing, and northern shaanxi. at present, the specifications of the shenkai coiled tubing bops have been fully covered, with a diameter range of 2 9/16”-7 1/16” and a rated working pressure of up to 15000psi(103.5mpa)!

(application site of an oilfield in southwest china)

(application site of an oilfield in northwest china)

as the core device to ensure safe production, the coiled tubing bops is used to close the wellhead during drilling, oil testing, workover, completion, etc., which is a safe sealed well control device to prevent blowout accidents. multiple specifications can be selected based on the type of operation and operating environment.

the continuous tubing bops consists of a bop box and a four-ram continuous tubing bop, which are installed on the continuous tubing operation vehicle.

the bop box is a wellhead pressurized sealing equipment. under the action of hydraulic control pressure, the packing unit inside the bop box firmly wraps the coiled tubing, and effective sealing between the wellhead and the coiled tubing can still be achieved when the coiled tubing is lifted or lowered.

the four-ram continuous tubing bop has four ram chambers, which are equipped with blind, shear, slip, and pipe rams from top to bottom to control the orifice pressure when the coiled tubing is in a stationary state.

4.06”-10000psi bop box and four-ram continuous tubing bop

for many years, shanghai shenkai petroleum equipment co., ltd. has established a comprehensive quality control system for continuous tubing bop, including product design, processing, assembly, and testing, strictly controlled product quality, and made unremitting efforts to continuously improve the safety and reliability of equipment.